Goldsmith & Jewelry

Elettrolaser: Laser Technology at the Service of Goldsmithing Excellence

In the world of goldsmithing, precision and quality are essential to create unique jewelry. Elettrolaser designs and manufactures laser welders, marking systems, and laser cutting machines specifically designed to support artisans and manufacturers in the processing and repair of jewelry and precious accessories.

For ultra-high precision microwelding, Elettrolaser uses advanced Nd:Ce:YAG laser technology with a 1064 nm wavelength. This ensures outstanding performance in terms of quality, control, and fine detail. Thanks to the latest innovations—such as SMSP waveforms and the smooth Gaussian spot—our welds are remarkably stable, uniform, and free from defects.

Elettrolaser offers a full range of welding machines designed to meet every need, from small workshops to large-scale production. Dado and Dado 2.0 are ideal for small laboratories carrying out quick operations, offering compactness and ease of use. The MS 3.5 is available in three power levels, making it versatile and suitable for both artisan workshops and professional production. The Master 4.0 and Master 4.0 Plus series combine precision, speed, and efficiency, adapting to different types of processing. Finally, the Mega series, designed for intensive and large-scale applications, delivers power, reliability, and aesthetic quality.

Our laser markers guarantee a very long operational life, ensuring consistent performance over time. The Fiberlux Nano is a high-quality entry-level solution that allows marking and engraving on any metal with maximum precision and versatility. The LuxMark series, on the other hand, is a more advanced solution, designed to meet the needs of medium and large-scale production environments.

Finally, OPERA is a one-of-a-kind machine, the first in the world to combine laser source and CNC, enabling marking, engraving, cutting, burnishing, and diamond cutting all in a single solution.

Laser Welding Machines

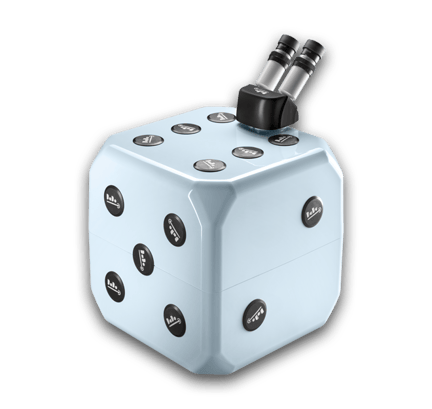

DaDo DaDo 2.0

- Average power (Watts): 10

- Peak power (kWp) : 1,8 | 2,5

- Frequency (Hz): 1,5 - 4

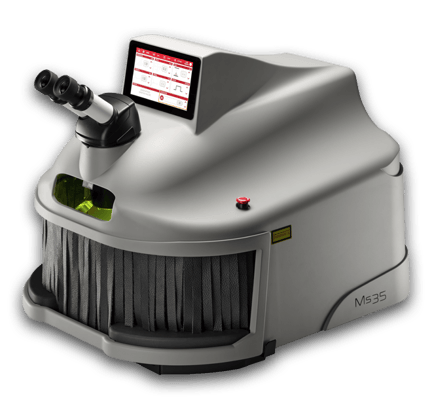

Ms 3.5

VERSION 35J / 80J / 165J

- Average power (Watts): 30 | 30 | 75

- Peak power (kWp): 3 | 4 | 6,5

- Maximum energy (Joules): 35 | 80 | 165

- Frequency (Hz): 0,5 - 20

Master 4.0

VERSION 100 / 200 / 300

- Average power (Watts): 80

- Peak power (kWp): 9

- Maximum energy (Joules): 225

- Frequency (Hz): 0,5 - 30

MEGA 5.0

VERSION 20 / 30

- Average power (Watts): 90

- Peak power (kWp): 10

- Maximum energy (Joules): 245

- Frequency (Hz): 0,5 - 30 Hz

MEGA 6.0

VERSION 100 / 200 / 300 / 400

- Average power (Watts): 100

- Peak power (kWp): 11

- Maximum energy (Joules): 255

- Frequency (Hz): 0,5 - 4

MegaHit 300

- Average power (Watts): 300

- Peak power (kWp): 15

- Maximum energy (Joules): 300

- Frequency (Hz): 0,5 - 50

CLW

- Average power (Watts): 40 - 300

- Peak power (kWp): 3,6 - 12

- Maximum energy (Joules): 25 - 80

- Frequency (Hz): 0,5 - 40

Laser Marking and Cutting

OPERA

- Type: Laser + CNC

- Laser power (Watts): 20 - 60

- Maximum marking area (mm): 100x100

- Maximum CNC area (mm): 200x140

FIBERLUX NANO

VERSION 30 / 60

- Laser source: Fibra | MOPA

- Laser class: IV

- Z-axis: Manuale

- Head speed Galvo: 5000 mm/s

Luxmark S

- Laser source: Fibra | Green | UV

- Laser class: I

- Z-axis: Motorizzato

- Workpiece height: max 18 cm

Luxmark M & TOP

- Laser source: Fibra | Green | UV | CO2

- Laser class: I

- Z-axis: Motorizzato

- Workpiece height: max 35 - 37,5 cm

Luxmark M-TOP 200 CO2

- Laser source: CO2

- Laser class: I

- Z-axis: Motorizzato

- Workpiece height: max 15,5 cm

Luxmark W15

- Laser source: Fibra | Green | UV | CO2

- Laser class: I

- Z-axis: Motorizzato

- Number of Pallets: 15